Seaming is the most recognized problem in the synthetic turf industry today. The synthetic turf industry has evolved over the past couple of decades and with advanced technology and research and development, synthetic turf manufacturers are producing thicker “real like” turf. However, these changes have created more difficult installation processes. This month, ASK JW is starting a 3-Part series on “Seam Integration”. This exciting series will cover anything and everything that has to do with creating “Invisible Seams”.

“Always maintain a good attitude and a yearning to be the best at what you do and love”

JW

I have spoken to thousands of installers all over the globe and the number one question that continually gets asked, year after year, is “How can my team and I become better at seaming turf”?

Creating invisible seams takes more than placing turf side by side. Understanding the dynamics of the synthetic turf and how to join two sections together without seeing the seam is a challenge. There are many factors that go into invisible seams – however, having the attitude of wanting to be better is all you need.

To start off this series, I have chosen the words below that I feel will be the driving force behind your success in creating invisible seams:

- Pride

- Time

- Patience

- Materials

- Practice

- Confidence

- Craftsmanship

- Mistakes

- Manipulation

- Repairs

- Troubleshooting

- Maintenance

PRIDE – Taking pride in your workmanship is the first step. Many turf installers don’t seek passion for their work, and it shows. Landscapers that have added synthetic turf to their resume focus primarily on installing irrigation, plants, trees, hardscape, and small amounts of synthetic turf. I have witnessed hundreds of “Hall of Shame” installations and found that there are installers/landscapers that don’t care about being better at synthetic turf. They can slap down a small piece to accent their landscape design but don’t have a clue when seaming multiple sections together. Most installers don’t recognize a bad seam until the homeowner points it out…they try to fix it… make it worse …then call me!

By the end of this 3-Part series, it will be easier for you to take pride in your work knowing your seams will always look “invisible”.

TIME – Having little or no time to install seams will always backfire on you! The most important part of installing synthetic turf is “SEAMS”. You can always fix an edge. You can always add more infill. You can always brush up the area to look better, but you can never hide a bad seam. An invisible seam doesn’t become invisible by itself. Having and taking the time to learn, practice, and hone your craft will only make you better. Every seam may be a challenge, but when the installation is complete you will be proud to be questioned: “where are the seams”?

PATIENCE – With time comes patience. If you are not a patient person then you may want to stop reading and seek a new career. Perfecting seams requires patience. If you are allowed the time, then you can be patient. You are dealing with two sections of turf, seam tape, glue, and a surgically sharp knife, so yes, you will need patient!

“Don’t beat yourself up…creating invisible seams will not happen overnight”.

JW

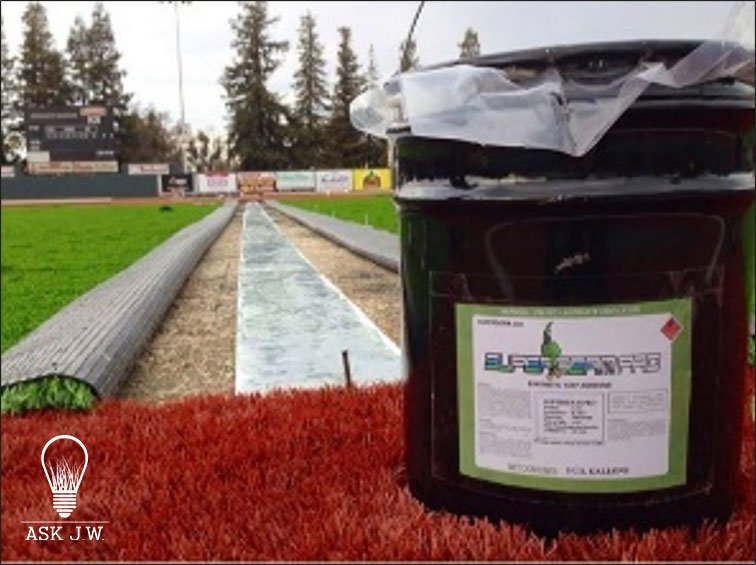

QUALITY MATERIALS – Having quality materials will produce quality seams.

Securing two sections of turf together from the bottom allows the top fibers to remain new out of the roll. That means no fiber manipulation which creates the “invisible seam”. In this series, you will learn how seam tape and adhesive may seem messy and more time consuming, but this series will teach you how fast and perfect your seams can be by following steps and methods that I have created to ensure “Invisible Seams”.

PRACTICE – As they say, “practice makes perfect”. This is so true with creating invisible seams in synthetic turf. I get asked “JW, how can I practice seaming when I don’t want to make a mistake on a contracted project”? You should never practice on a client’s installation. As I mentioned earlier, installing seams can be a crap shoot of how they will turn out until you gain confidence in your cutting skills. I recommend practicing on remnants that will not be used so that you can make mistakes and learn from them. It’s not a good thing to make mistakes on client’s projects but it is going to happen.

In this 3-Part series I will teach you tips and tricks to ensure you can get your practice in while preventing mistakes, so don’t stress out.

CONFIDENCE – Getting good at something always takes practice but having faith in yourself builds confidence. Learning seam integration will create invisible seams. Invisible seams build confidence in knowing you can take on any turf installation and be responsible for making large projects with multiple seams look seamless.

CRAFTSMANSHIP – When you have built confidence within yourself, you will be the one that will be taking the lead on the installation of seams. You will be the one that builds your skills into a craft. Your will and need for perfecting seams will make you a leader in the industry.

Within this 3-Part series you will gain knowledge, tips, and tricks that will add to your craft so you can say… “guess where the seam is”?

LEARNING & MISTAKES – Making mistakes is how I became the best at seams. Getting skilled requires more than handling turf and cutting with a knife. You must learn about thermal expansion/contraction and how it causes movement during and/or after the seaming process and why it causes visible seams. It takes research and studying on your part to be the best.

“ASK JW’s Seam Integration” provides education that will assist you in becoming the best at turf seams.

SEAM REPAIR – Believe it or not, repairing your own mistakes makes you better by bringing awareness to why you made the mistake in the first place. You cannot be the best at seams if you don’t acknowledge why the mistake happened. Getting good at repairing your own mistakes will build confidence and allow you to anxiously fix others and brag about it. In this series I will teach you how to make repairs to your mistakes so that you can do the same.

TROUBLESHOOTING – In this series, you will learn tips on what to look for when facing material defects, how to overcome them, and still be able to create “invisible seams”.

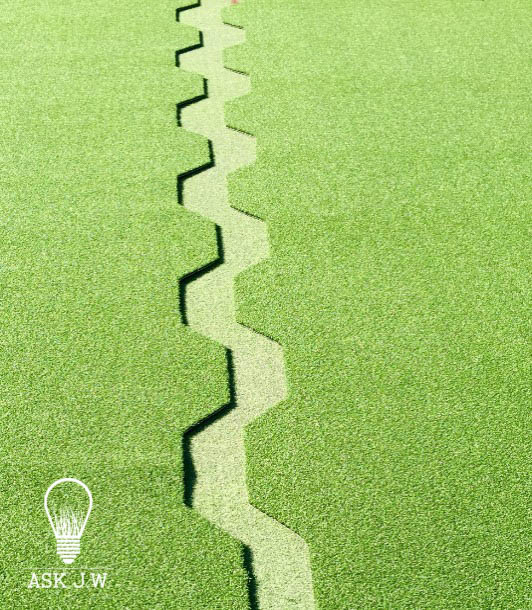

MAINTENANCE – In this series, you will learn to create seams for longevity. When seams in synthetic turf become beaten down and look like the “parted sea”, a judgment call will be made to either repair or replace it. “ASK JW Seam Integration” creates stronger seams that last longer than straight seams.

Seaming is the most recognized problem in the synthetic turf industry today. The synthetic turf industry has evolved over the past couple of decades and with advanced technology and research and development, synthetic turf manufacturers are producing thicker “real like” turf. However, these changes have created more difficult installation processes. This month, ASK JW is starting a 3-Part series on “Seam Integration”. This exciting series will cover anything and everything that has to do with creating “Invisible Seams”.

“I look forward to sharing this 3-Part series of Seam Integration with you”.

JW

For more information regarding Seam Integration, contact JW at askjw@sgwcorp.com or call 888.846.3598

Other Topics:

About SGW

Learn more about SGW

Certifications

IPEMA, Lead-Free, and CAD Details

Warranties

Our Industry Leading Warranties

Ask an expert

See if we’ve answered your questions

Media

Our tried and true steps for installation

Blog

Learn about our turf in depth

Here to help

Our Commitment

We are committed to providing the best artificial turf products at competitive prices. Our warehouse carries the most advanced synthetic grass products available, engineered to look and feel like real grass. Every turf product is made with high quality materials that are safe for everyone, especially children and pets.

Industry Leaders

SGW Canada has always stood out among competitors, offering new products with the latest technology.

Service Oriented

The only thing better than our grass is our customer service. Our staff is committed to providing the best experience possible for our clients.

Quality Driven

At SGW Canada we only offer products that maintains a high standard of quality. Backed by up to a 15 year warranty, the best in the industry.